| |

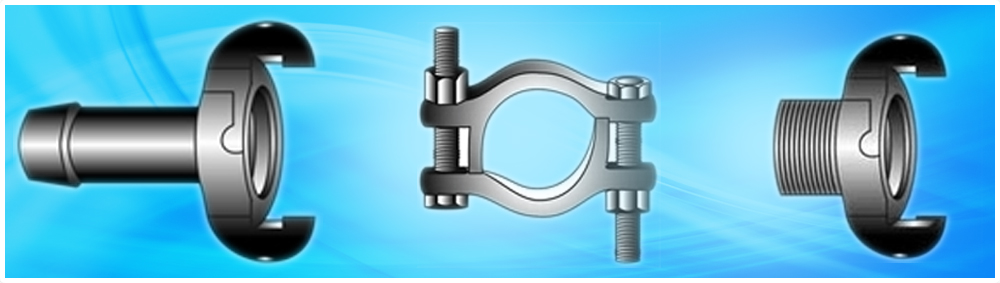

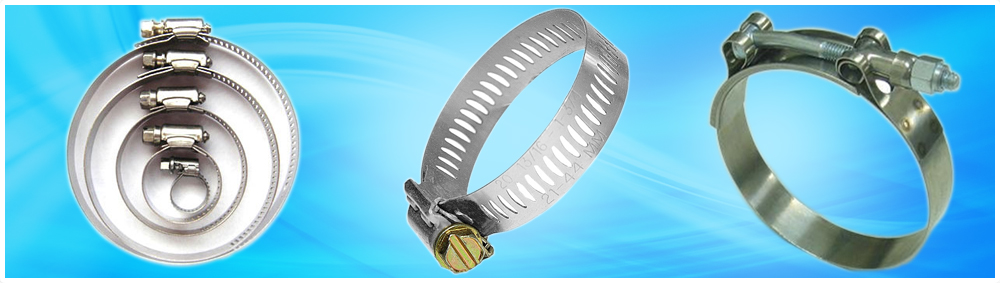

HOSE CLAMP |

| |

|

|

Materials |

Products are made from CR

Mild Steel, Carbon steel, alloy steel and

stainless steel materials to meet as per

customers requirements. |

| |

Quality Standard |

All these years Klipco

adhered and laid stress on Quality products

only i.e. TQM and could build world class

quality products exceeding the requirements

stipulated in different Clamps

specifications.Klipco is a certified Co. for

TQM under ISO:9001, ISO:9002 and

ISO/TS:16949.Klipco Worm Drive Clamps are

tested as early as 1965 and approved by

National Test House. ISI mark was obtained

in the year 1984/85. From 1966 meeting OEM

requirements particularly of Automotive,

Tractors, Defence, Engineering, Chemicals,

Oil fields etc, and general home and export

markets. |

|

|

CAPABILITY , SALES AND

SERVICES: |

Klipco is now producing

more than 1,80,000 Hose Clamps a day, in

various sizes, designs and materials, in

their four plants spread over 1,00,000 sq.ft

area, with India wide network for sales and

service at Delhi, Mumbai, Chennai, Kolkatta,

Jamshedpur, Pune, Bangalore, Hyderabad,

Indore, Lucknow, Ahmedabad, Baroda and

Jabalpur & have authorised Dealers in major cities.Klipco has in house facility for

Tool-room, Fabrication of special purpose

machine Tools, Heat Treatment facility,

plating plants with its own CAD-CAM

centres.Constantly, initative is taken on

R&D for technology development and up-dating

the products to meet the ever changing

demands of valued buyers. |

| |

SPECIFICATION: |

SAE & J 1508-1996 (Type : F:1: M, Mx : HD & SLHD. Hose Clamps.) |

IS : 4762-2002, BS : 5315/91, DIN : 3017. |

DIMENSION OF CLAMPS:Type F

(SAE-J-1508) |

|

SAE

Sizes |

IS: 4762

Sizes |

Sizes |

BS : 5315

Sizes |

X

Working Range |

| Min |

Max |

| - |

12 |

000 |

12 |

9.5 |

12 |

| - |

16 |

00M |

16 |

11 |

16 |

| 6 |

20 |

00 |

20 |

13 |

20 |

| - |

22 |

0 |

22 |

16 |

22 |

| 8 |

25 |

25A |

25 |

18 |

25 |

| 10 |

- |

0X |

- |

|

|

| 12 |

30 |

1A |

30 |

22 |

30 |

| - |

35 |

35A |

35 |

25 |

35 |

| 16 |

- |

1 |

- |

30 |

38 |

| - | 40 |

1X |

40 |

30 |

40 |

| 20 |

45 |

45A |

45 |

35 |

45 |

| 24 |

50 |

2A |

50 |

35 |

50 |

| - |

55 |

2 |

55 |

40 |

55 |

| 28 |

60 |

2X |

60 |

45 |

60 |

| 32 |

65 |

65 |

- |

50 |

65 |

| 36 |

70 |

3 |

70 |

55 |

70 |

| 40 |

- |

75A |

- |

60 |

75 |

| 44 |

80 |

3X |

80 |

60 |

80 |

| 48 |

90 |

4 |

90 |

70 |

90 |

| 52 |

- |

- |

- |

75 |

95 |

| 56 |

100 |

4X |

100 |

85 |

100 |

| 60 |

110 |

110 |

- |

90 |

110 |

| 64 |

115 |

- |

- |

95 |

115 |

| 72 |

120 |

5 |

120 |

100 |

120 |

| 80 |

130 |

130A |

- |

110 |

130 |

| 88 |

140 |

6 |

140 |

120 |

140 |

| - |

- |

6X |

- |

130 |

150 |

| - |

- |

160A |

- |

140 |

160 |

|

| |

|

|

Size |

Outside Diameter

of Hose |

Size |

Outside Diameter

of Hose |

| 7 |

150 |

175 |

13 |

300 |

325 |

| 8 |

175 |

200 |

14 |

325 |

350 |

| 9 |

200 |

225 |

15 |

350 |

375 |

| 10 |

225 |

250 |

16 |

375 |

400 |

| 11 |

250 |

275 |

17 |

400 |

425 |

| 12 |

275 |

300 |

18 |

425 |

450 |

|

| |

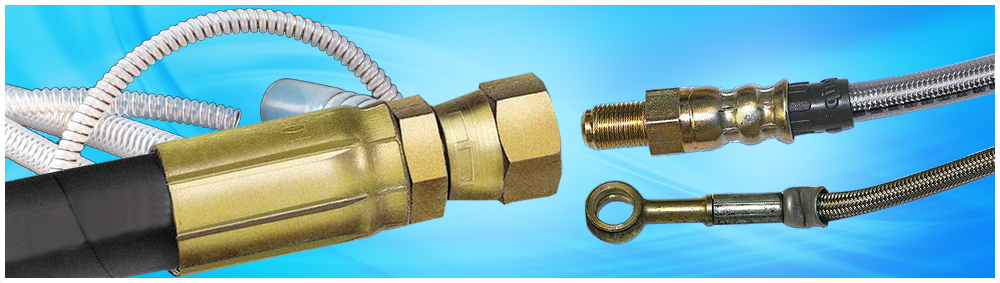

GENERAL USES: |

|

|

Automotives, Trucks,

Tractors, & Two Wheelers |

|

|

Aircrafts, Space &

Satellites |

|

|

Atomic Plants |

|

|

Air Conditioning |

|

|

Engineering, Machine Toos, &

Pneumaties |

|

|

Hydraulic & Pneumaties |

|

|

Laboratories |

|

|

Marine Navy & Defense |

|

|

Mines |

|

|

Oil, Gas & Refinery |

|

|

Plants- Steel, Chemical,

Fertilizers Cement etc. |

|

|

Plantations, Agriculture &

Domestic |

|

|

Railway & Metros |

|

|

Sewage Treatment Plants |

|

|

Traffic, Signals & Hoardings |

| |

|

|

|

|

|

|

|

|

| |

|